Cathodic Protection Solutions

- Cathodic Protection Solutions LLC for AMPP certified corrosion engineers and cathodic protection system design, installation, testing and monitoring. We conduct cathodic surveys, atmospheric surveys, pipeline coating applications and inspections, internal pipeline corrosion control, ISN contractor services and cathodic equipment manufacturing and repair.

- In-Line Inspections according to the requirements of the Pipeline and Hazardous Materials Safety Administration (PHMSA), the inspection reporting deliverables include the Pigging Report, Magnetic Flux Leakage Report (MFL), Electronic Geometry Profile Report (EGP) and a Summary Report.

- Chemical Services for problems and efficiency cost reductions for pipeline chemical treatment programs. We test, evaluate and diagnose problems, such as internal corrosion, and evaluate the overall program efficiency for cost, providing expert recommendations and solutions.

- Hydrovac Excavation for the nondestructive excavation of underground oil pipelines, utilities and structures. We also create right of ways, clear land and provide vacuum truck service in Midland and Permian Basin.

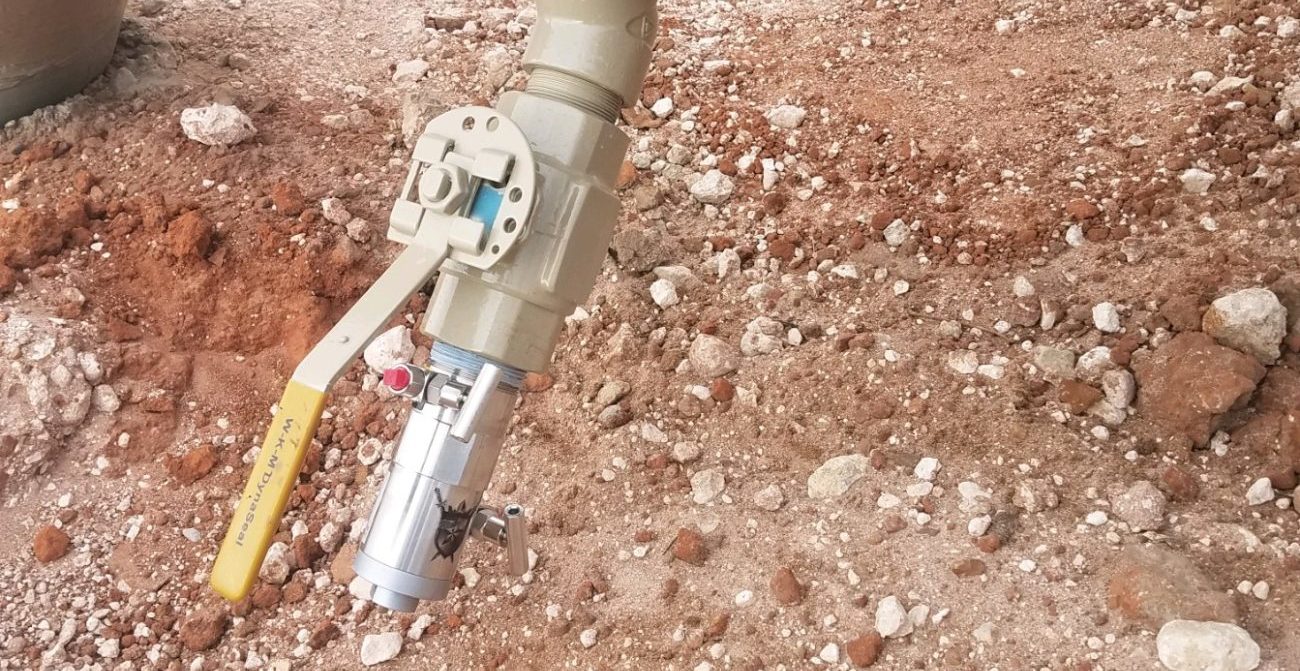

- Internal Pipeline Corrosion Control. We invented the Excalibur Shield (US Patent No. 10337979), the most comprehensive internal pipeline assessment, control and monitoring device. Weight loss coupons and internal fluid and solid sampling are used to produce leading edge pipeline analysis.

- Surveys, Inspections, Applications & Monitoring. We provide expert cathodic protection pipeline surveys, coating inspections, coating applications and install remote monitoring systems using rectifiers. Cathodic surveys include Baseline / Native, On, On / Off using a 100MV shift. We also test and service well casings, underground and above ground storage tanks, telecom towers, anchor shafts, apartment complexes and gas station tanks.

- Test Stations, Junction Boxes and Rectifiers. We design, manufacture and install client custom test stations, junction boxes, negative bond boxes and positive bond boxes. Safety, regulations, performance, cost and ease of installation all factor into the test station design.

- View the Association of Materials Protection and Performance (AMPP) video presentation by Joe Gallo Jr. and Sagar Patil: The Excalibur Shield. View more videos; Company Overview, MIC, Case Study and Weight Loss Coupons and Excalibur Shield Overview

- Cathodic Protection Solutions LLC customers include major oil and gas companies Advantage PL, Alpha Crude Connectors, Ameredev, American Midstream, Beata Crude Connectors, Brazos Midstream, Canyon James Lake & Grerson Springs, Carrizo Permian, Chevron, Concho, ConocoPhillips, Diamondback, Energy Transfer, Enterprise, Frontier, Kaiser Francis, Kinder Morgan, Kinder Morgan El Paso, Kinetik, LPC Crude, Medallion, Navitas, Noble Midstream, PennTex Permian LLC, Plains All American, Plains Marketing, Reliance, Slant, Tema Oil and Gas, Turpin Engineering, Vaquero Midstream, Vitol, West Texas Gas (WTG), WhiteWater Midstream, Vaquero Midstream.