Cathodic Test Station Design & Manufacturing

Since 1991, Cathodic Protection Solutions has designed, manufactured and installed thousands of cathodic protection test stations, junction boxes and bond boxes. We produce Surveys for oil and gas pipelines and storage tanks to determine the best locations for above or below the ground. We are located in Midland, Texas, and serve the Permian Basin.

We use AMPP certified technicians ensure quality, safety and reliability of the design and implementation. Whether it’s a simple CP test station with two wires connected to the pipeline or test stations with remote monitoring, we can do it all. As required, we also install pipeline markers, utility signs, utility markers and dome marker posts by regulation.

Custom Specifications

Test stations are essential to the cathodic protection program and used to monitor operational parameters and overall effectiveness. Custom specifications include 1 1/4″ or 3″ PVC versus steel U Post, #10 or #12 solid versus stranded wiring, 3/4″ steel head, 3/4″ rigged conduit and back plate.

Safety, regulations, performance, installation effort and cost are the most important considerations in the test station design process. Cathodic test stations provide electrical contact with buried pipelines for corrosion protection and remote corrosion monitoring. Test stations are also designed for durably to last for years of service.

All cathodic test stations are manufactured using non-corrosive, non-conductive, light weight durable materials to protect from corrosion or back scratching cattle.

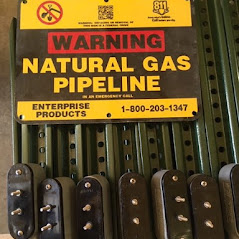

The two wire test station is the most frequently used, two wires make it possible to check pipe-to-soil potential voltages as a D/C current is applied to the pipeline. The test stations should be located where technicians can gain convenient and practical access access. Space is left above the test station head on the mounting u-post to allow for company pipeline warning signs.

Test stations measure the potential between the pipeline and electrode using voltage readings from remote monitoring, less negative potential indicates higher levels of cathodic protection. Measurements are taken at every road crossing, pipeline crossing, and every mile of pipeline plotted for a highly accurate corrosion assessment.

We also maintain and service all test stations including new box covers, retention screws, cover gaskets, terminal nuts and screws. We also install pipeline markers, utility signs, utility markers and dome marker posts, as required.

Anode Junction Boxes

We design junction boxes to survive the elements using .001Ω type SS or other various of shunts stainless steel enclosure, galvanize enclosures or no metallic enclosures, insulated panels, copper bus bar, 0.01Ω JB shunts, V50MV SW shunts, resistors or rheostats or adjustable resistors, meters and switches, blocking diodes and copper terminal lugs for assembly. Junction box mounting options include pole mount channel, wall mount tabs or custom client junction box mounting specifications.

For a consultation, please call (432) 230-6955.

Click here to Request a Proposal